|

Barrel installation using the BugNut The BugNut works in a similar manner to the traditional Savage barrel nut system, but the barrel is machined differently to accept the different dimensions of the nut. Savage nuts are not useable with a BugNut pre-fit barrel; BugNuts may work on a Savage or Remage pre-fit barrel, but will leave unsightly gaps between the nut and barrel, and may leave exposed threads on the barrel tenon. BugNut Pre-fit barrels are made specifically for a certain action, and if applicable, with a certain thickness recoil lug. In some cases, switching to a thicker recoil lug than what the barrel was machined for can cause a dangerous situation.

The Tikka/Ruger BugNuts are not designed to work with factory barrels - only custom barrels cut to fit: Instructions: Remove existing barrel, and clean action threads, lug abutments, and action face (if necessary) with a brush and solvent. If you are removing a factory barrel, a wire brush may be necessary to remove rust, Loctite, or other material present in the action threads. Clean your pre-fit barrel blank with solvent and air pressure, making sure there is no debris or packing dust on the threads or in the chamber. Clean the inside of the nut as well. When all is acceptably clean, lube the barrel tenon threads with a light amount of lube. I use Loctite C5-A (copper based), you can use grease, anti-seize, or other appropriate high pressure lube.

It is recommended to remove your plunger ejector from the bolt, if equipped. This will interfere with the “feel” of the bolt when checking headspace. Most are held in place with a cross pin, and retain the ejector under spring pressure. Take care to not launch your ejector and spring when removing your punch from the cross pin hole.

Screw the BugNut all the way up the barrel until it stops on the tenon shoulder. If you are using an action with removable recoil lug (Remington, Savage), use a fixture to hold the recoil lug in place and prohibit lug movement/rotation when under torqueing force of the nut.

Place the barrel in your barrel vise, gripping the barrel near the breech and nut, do not clamp on the nut. Insert your clean headspace GO gauge into the chamber, insert your bolt into your action and close the bolt. You can leave your trigger in the action, but put the safety on if possible

Screw the action on to the barrel tenon. It should screw on and stop short of the nut. If it does not stop short of the nut, stop the install immediately and call Southern Precision Rifles.

Your barrel is now set for minimum SAAMI headspace; a small amount of additional clearance on your chamber is recommended. Unscrew the action approximately the width of two or three scope base holes [about 2-3 degrees of rotation], and then unscrew the nut towards the action face/recoil lug. Snug the nut against the action with moderate finger pressure only, and remove the headspace gauge. Place a small piece of scotch tape (approx. .002 thick) or a small piece of notebook paper (.003-.004) either on the bolt face, or on the GO gauge base.

Insert the gauge and close the bolt. You should feel some resistance with whichever “spacer” you chose to use. If youre satisfied here, and you have a no-go gauge, remove all tape or paper and insert the no-go now. The bolt should not close on the no-go gauge. If the bolt closes on the no-go, rewind, double check, and start over. If all is good, remove the bolt and gauge

Assemble your BugNut wrench over the nut in whichever orientation suits you, and makes torqueing the easiest. Insert an action wrench in the action. In opposing motions, you want to torque the nut against the action, while not allowing the action to unscrew. You are not torqueing the action into nut, merely resisting the actions tendency to unscrew with the nut, only the nut should move.

Recommended torque values:

After desired torque is achieved, re-check your headspace with whichever method you used initially. If your headspace has changed, rewind and re-headspace again. Install the ejector back into the bolt, patch out the chamber and bore of the barrel, and you’re ready to go shoot

if you have questions or concerns call 239-289-2338

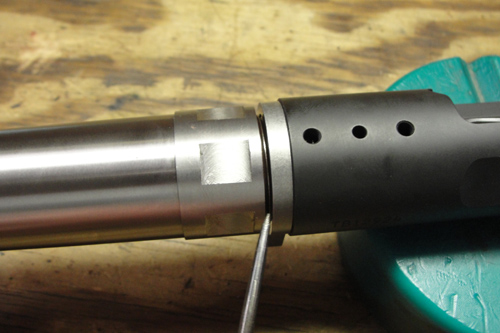

Tikka/Ruger Magnum Bugnut installed on a Tikka action with the smaller standard Tikka/Ruger Bugnut without an action.

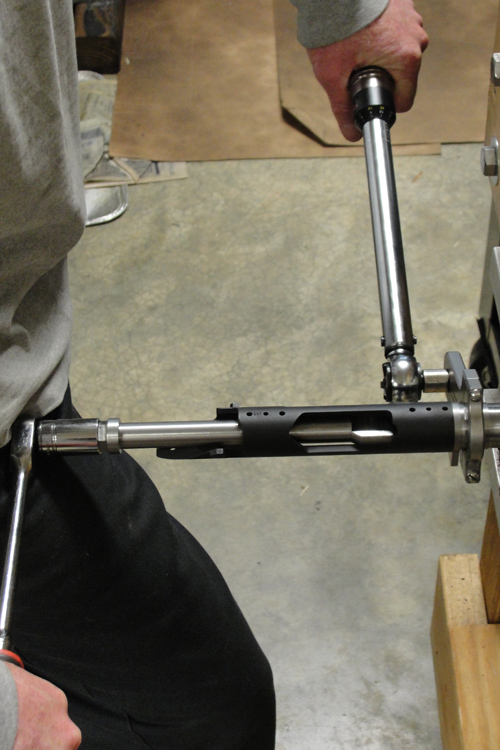

The Tikka/Ruger Bugnuts are not designed to work with factory barrels - only custom barrels cut to fit.

Tikka/Ruger standard Bugnut installed on a Tikka action

|